Carbon MTB Rims

categories

recent posts

A Strange Little Hole in the Bicycle Rim - Drain Hole

Today we will explain to you why professional bicycle rims need to drill this drain hole.

Even as tight as the spokes you can, the water can still get inside through spoke holes as well as valve hole. After bike cleaning, riding in rain, or crossing flooded terrain, the water greatly possibly goes into rims, and maintains for many weeks and even months if not properly deal with.

The accumulated water inside a hollow rim add weight, which makes bad effects, such as bike imbalance, noisy and poor control to the bike. Another critical problem is that the water will corrode metals including steel spokes, aluminum alloy nipples and brass nipples.

Drain holes provide an exit for accumulated water inside rim during rolling or stationary by gravity and centrifugal forces.

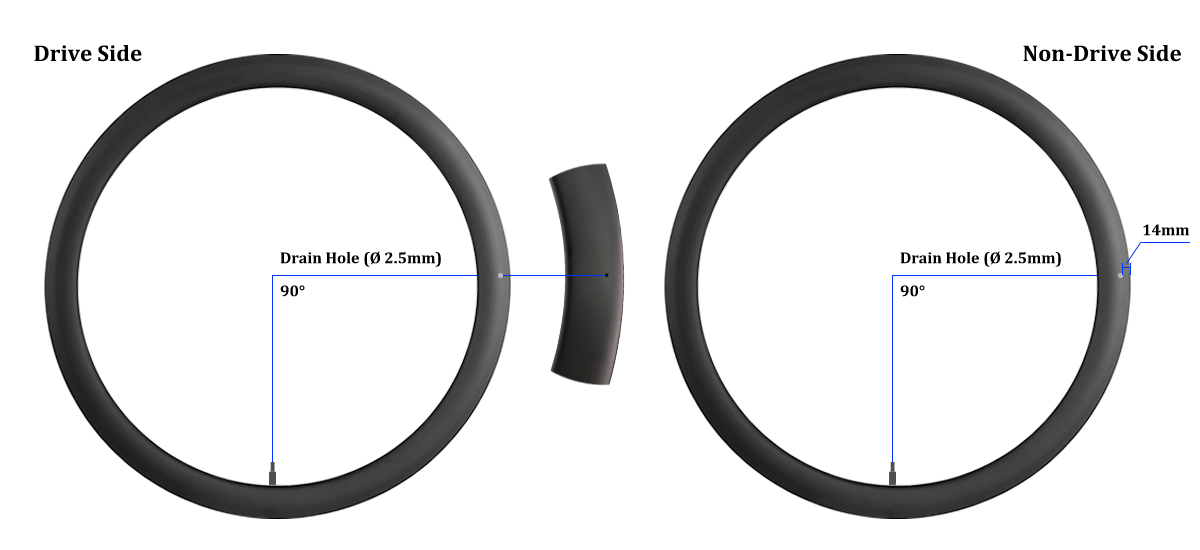

We drill 1 holes in each pc of carbon road rims (total 2 holes on each rim). The holes are drilled 90° to the valve hole. They are tiny holes with only 2.5mm diameter on the chamber between the section of spoke holes and rim bed. It is 14mm away from rim edge. One hole is on the drive side and the other is on non-drive side. Let water out as easy as possible!

Another function of such tiny hole is some kind of pressure relief, especially for tubeless tire using by high pressure shock pump. Maybe stupid question but do you install tubeless tape/valve properly? If not, the abundant high pressure will leak from tire bed and get into the “stomach” of carbon rims. If the volume of leak air is too much while inflation continues, it may lead to blasting of carbon rim! Though the chance is not high, it is a nightmare if happened. Thus, more and more brands tend to drill such water drain hole.

We are always optimizing our products to give riders a better riding experience.

Check out our top- quality carbon bicycle rims here>>

copyright © 2025 LightCarbon Composite Technology Co.,Ltd.all rights reserved.

the professional team to service !

+86-592-6380131

+86-592-6380131 info@lightcarbon.com

info@lightcarbon.com Wendy | LightCarbon

Wendy | LightCarbon +86 18405052114

+86 18405052114